|

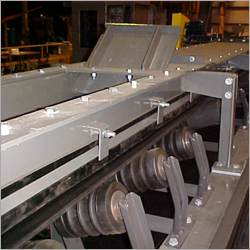

V Plough Internal Scraper

V Plough Internal Scraper Specification

- Machine Type

- Conveyor Belt Accessory

- Control System

- Mechanical

- Power Source

- Mechanical (Belt Movement)

- Accessories Type

- Belt Cleaner

- Surface Treatment

- Powder Coated / Paint Coated / Galvanized

- Technology

- V Plough Scraper Mechanism

- Automation Grade

- Manual/Automatic

- Operating Pressure

- Atmospheric

- Accuracy

- High

- Material

- Mild Steel (MS), Polymer Blade

- Function

- Removes material buildup from conveyor belts

- Application

- Belt Conveyor Cleaning in Industries

- Voltage

- No electrical supply required

About V Plough Internal Scraper

As a reputed manufacturer of the industry, we are engaged in offering an exceptional range of V Plough Internal Scraper. These scrappers are used in bulk material handling belt conveyors to avoid material carry back and reduce spillage. We use modern machines and quality approved materials to design V Plough Internal Scraper, in sync with international quality standards. Before the delivery, we make sure that our offered range is packed very carefully so that no damage occurs during their transport.

Features:

- This self adjusting type scrapper has multi-tip that results in efficient belt cleaning

- Smooth operation, rugged design and fine finishing are some of the salient attributes

- Fully collapsible construction for simple maintenance

Advanced V Plough Scraper Mechanism

Utilizing a precision-engineered V Plough design, this scraper effectively diverts and eliminates debris from conveyor belts. The polymer blade glides smoothly across the belt, preventing damage while maintaining cleaning efficiency. Its construction ensures high performance even in rigorous industrial settings where continuous removal of material buildup is essential.

Durable Construction and Surface Treatment

Crafted from mild steel, the V Plough Internal Scraper guarantees lasting strength. Customers can choose from powder coated, paint coated, or galvanized finishes, each offering exceptional resistance to wear and corrosion. These treatments extend the scrapers operational life, making it suitable for demanding environments with frequent exposure to abrasive materials.

FAQs of V Plough Internal Scraper:

Q: How does the V Plough Internal Scraper operate on a conveyor belt?

A: The V Plough Internal Scraper works by utilizing the movement of the conveyor belt itself. The scrapers V-shaped polymer blade is mounted below the belt and sweeps away any material buildup as the belt moves, all without needing an electrical supply.Q: What industries commonly use the V Plough Internal Scraper in India?

A: Industries such as mining, cement, fertilizer, and bulk material handling widely use this scraper for belt conveyor cleaning to ensure smooth operations and prevent blockages caused by material accumulation.Q: When should you install a V Plough Internal Scraper on your conveyor system?

A: Installation is recommended during initial belt setup or when recurring material build-up is observed. Regular use significantly reduces maintenance intervals and potential belt damage caused by abrasive debris.Q: Where is the V Plough Internal Scraper positioned on conveyor belts?

A: The scraper is installed internally, just before the belts return pulley, ensuring debris is effectively removed prior to the belts return cycle and improving overall system cleanliness.Q: What is the process for maintaining this belt cleaner?

A: Routine checks for wear on the polymer blade and frame should be performed. Depending on surface treatment, touch-up or cleaning may be required to preserve the scrapers efficiency and lifespan.Q: Can the V Plough Internal Scraper be automated?

A: Yes, the scraper is available in manual and automatic versions. The automatic model integrates with existing control systems for seamless operation, minimizing manual intervention.Q: What benefits do industries gain by using a V Plough Internal Scraper?

A: Using this scraper reduces maintenance downtime, extends conveyor belt life, and ensures consistent product flow by preventing material accumulation, ultimately enhancing productivity and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Goods & Equipment Category

Pneumatic Sector Gate

Price 500000 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Mild Steel

Usage : Industrial

Surface Treatment : Polished

Product Type : Pneumatic Sector Gate

Pneumatic Butterfly Damper

Price 4000.00 INR / Piece

Minimum Order Quantity : 15 Pieces

Material : Mild Steel

Usage : Industrial

Surface Treatment : Polished

Product Type : Pneumatic Butterfly Damper

Jaw Crusher

Price 1000000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Mild Steel

Usage : Industrial

Surface Treatment : Polished

Product Type : Jaw Crusher

Dust Extraction System

Price 1900000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Mild Steel

Usage : Industrial

Surface Treatment : Polished

Product Type : Dust Extraction System

|

SINHA BMH SYSTEMS (INDIA) PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |